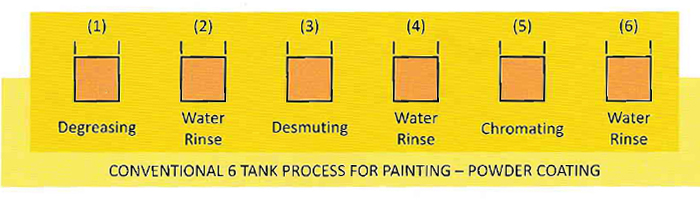

Pre-Treatment For Aluminium Casting

Degreasing

:- Removal of Oil,Grease & Oxide layer from aluminium surface.| PRODUCT | NATURE | CONC. | TIME | TEMP. |

|---|---|---|---|---|

| ALKLIN SERIES | ALKALINE DEGREASING | 5% w/v | 10-15 MIN | RT TO 60°c |

| OLOSOL SERIES | ACIDIC DEGREASING | 25% v/v | 5-15 MIN | RT |

Remarks

:-1.For light to heavy oil, light duty ALKLIN chemicals can be used. Desmuting step is compulsion with ALKLIN LD/LDS if used for heavy oil components. The same may be omitted for light oil.

2.For light to medium oil,OLOSOL SERIES of chemicals may be used. This does not require desmuting process.

Desmuting

:- Removal of Oil,smut and Oxide layer from surface-optional step.| PRODUCT | NATURE | CONC. | TIME | TEMP. |

|---|---|---|---|---|

| DI CLEANSER | COMBINED DEGREASING-DESMUTING | 2-5% v/v | 2-5 MIN | RT |

Degreasing can also be omitted as this has combined degreasing desmutin properties.

Articles should not by any chance be kept in this series of products beyond specified period of time.

Chromating

:- Gives amorphous chromate coating on aluminium surface.| PRODUCT | NATURE | CONC. | TIME | TEMP. |

|---|---|---|---|---|

| ALCHROM Y | YELLOW CHROMATE COATING | 1.5-2% v/v | 5-10 MIN | RT |

This coating prevents oxidation of aluminium die casting material and gives the necessary adhesion required for painting or powder coating.

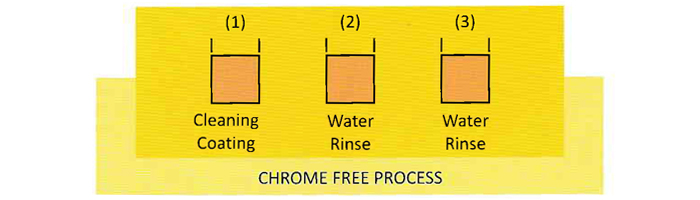

Cleaning Coating

:- Removal of Oil,Grease & Oxide layer & giving amorphous conversion coating on the surface.| PRODUCT | NATURE | CONC. | TIME | TEMP. |

|---|---|---|---|---|

| KLINKOT KP | ACIDIC CLEANING PLUS COATING. CHROME FREE COATING . |

5-15% v/v | 5-10 MIN | RT |

Advantages of the process

:-The process is simple-user friendly.

Very short process cleaning and coating takes place in the same chemical.

The process does not require any external heating.

The chemicals are chrome free hence environment friendly.

All the chemicals are RoHS compliant.

Very good adhesion for paint / powder coating.

Website Developed & Designed by – MWMEDIA

Copyright © 2016 – Dimetrics Chemicals. All Rights Reserved